DC201 & DC401

flow-dynamic dust separators

Filtrabit’s patented innovation for separating fine dust particles from gases is based on the principles of flow-dynamics and has created an entirely new category of dust control equipment.

Unprecedented performance of the separation core at the heart of the technology enables industrial clients to reduce their particulate emissions and meet strict environmental regulations.

| DC201 | DC401 | |

|---|---|---|

| Separation cores | 2 | 4 |

| Air flow | 2 400 m3/h | 4 800 m3/h |

| Air temperature | Up to 80 °C* | |

| Separation performance | 150 kg/h* (application specific) |

300 kg/h (application specific) |

| Separation capability | >99%** for PM2.5 and larger >96%** for smaller than PM2.5 (application specific) |

|

| Dimensions | 6.05m x 2.44m x 2.90m | |

| Weight | 5 300 kg | 6 000 kg |

| Dusty air intake | DN200 | DN300 |

| Clean air outlet | DN200 | DN300 |

| Dust outlet | DN80 | DN80 |

| Power | 400 V / 160 A | 400 V / 200 A |

| *Separation core tested independently at °600 C. **Proven in continuous operation with coke dust at the SSAB coke sieving plant in Raahe, Finland. |

||

Capital efficient solution

Filtrabit offers dust separation units on an operating lease model and together with partners, helps clients design the necessary hooding and ducting.

The operating lease option eliminates the need for large capital expenditures, helping respond to a constantly moving regulatory environment.

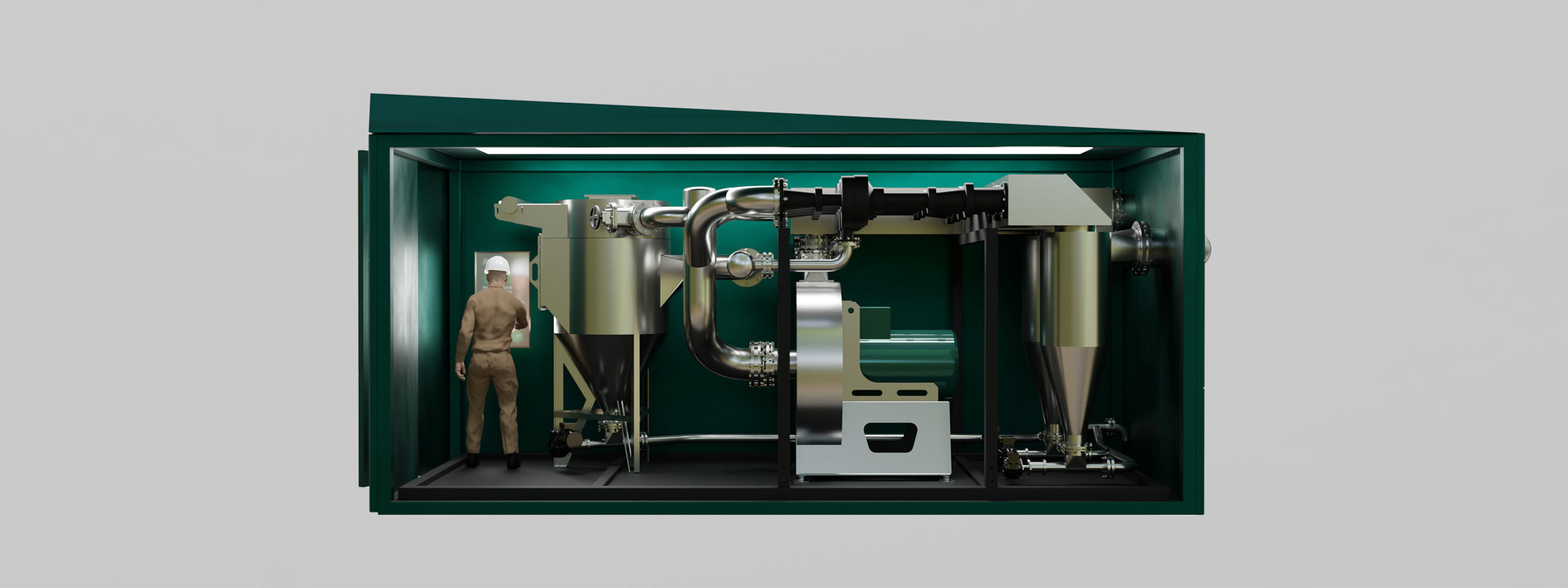

Modular units on the spot

The DC201 and DC401 models are built on a pallet and fit inside a standard shipping container, eliminating the need for significant construction work. Units can be mounted side by side and on top of each other, enabling exact tailoring of capacity.

The compactly sized units are serially produced and portable, allowing for quick installation and a flexible placement close to the source of the dust.

High performance

The separation core of the Filtrabit dust extraction system has been proven to be highly efficient in separating large volumes of coke dust, among other dust types.

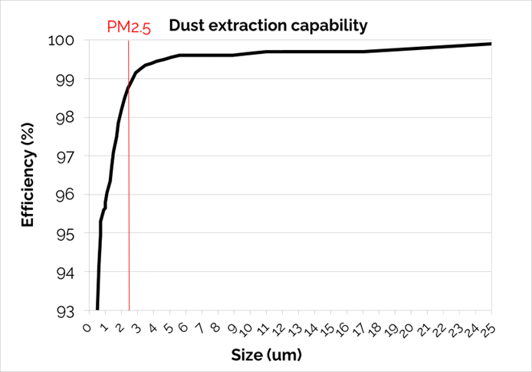

The DC201 system with two separation cores has been recorded extracting 150 kg of dust per hour in a high-density coke dust application. Tests showed over 99% efficiency for particles larger than 2.5 μm (PM2.5) and over 96% for smaller particles, as independently verified by Eurofins.

Separation efficiency is specific to the application and dependent on properties of the dust and intake gas.

Dust extraction measurements from the coke sieving plant of SSAB in Raahe, Finland.

Working principle

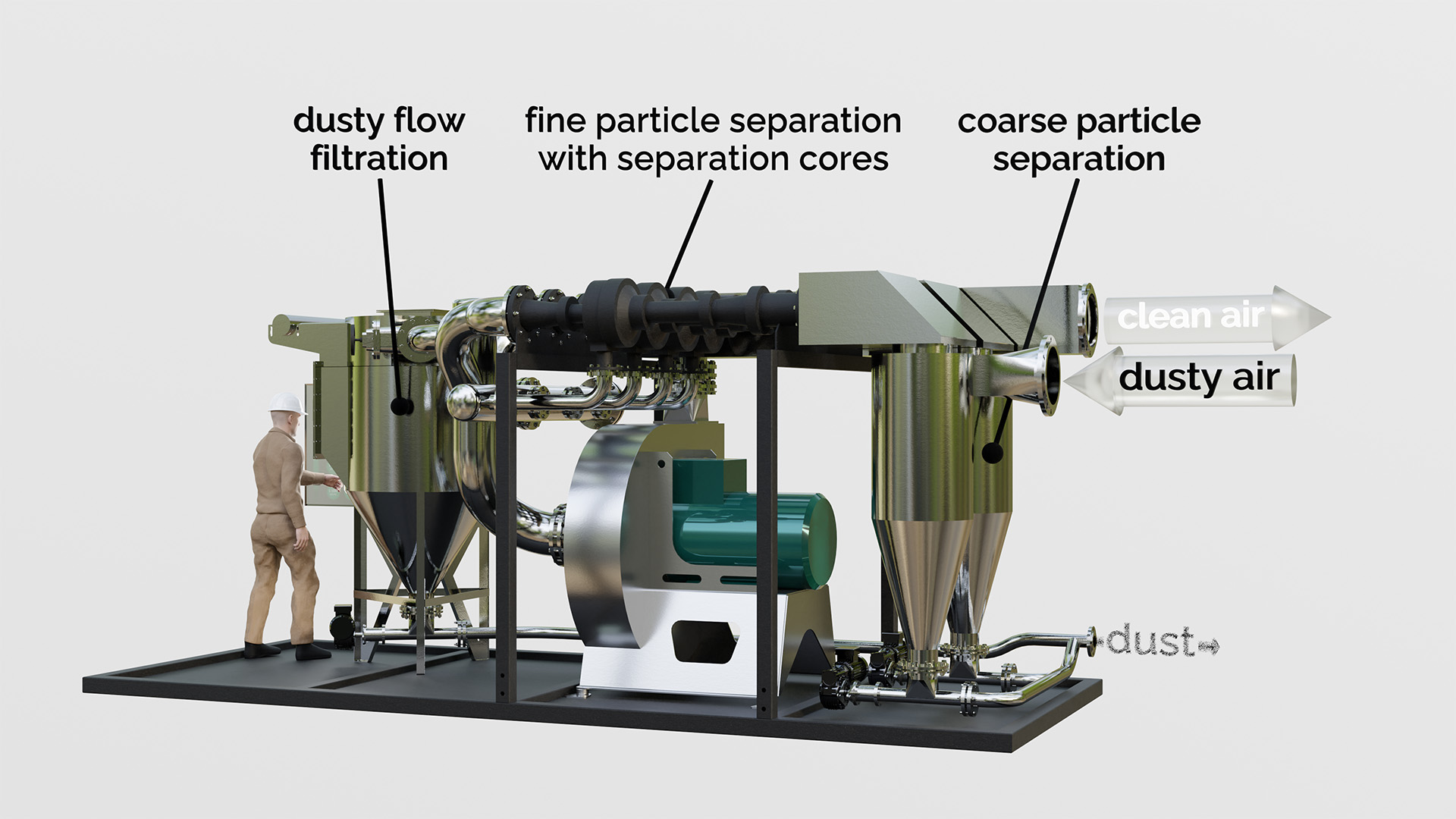

Main parts

- Pre-separator

- Separation core

- Dusty flow filter

- Vacuum pump

- Dust screw conveyor

Flow of operation

Dusty air is first brought into the coarse pre-separator, which removes the larger particles.

Finer particles continue to the separation core, which extracts them using Filtrabit’s patented method based on flow-dynamics.

Cleaned air proceeds directly to the clean air outlet, while the dusty flow continues on to the dusty flow filter.

After being filtered from residual air, the pure dust is fed into the screw conveyor, which delivers it out of the system through the dust outlet.

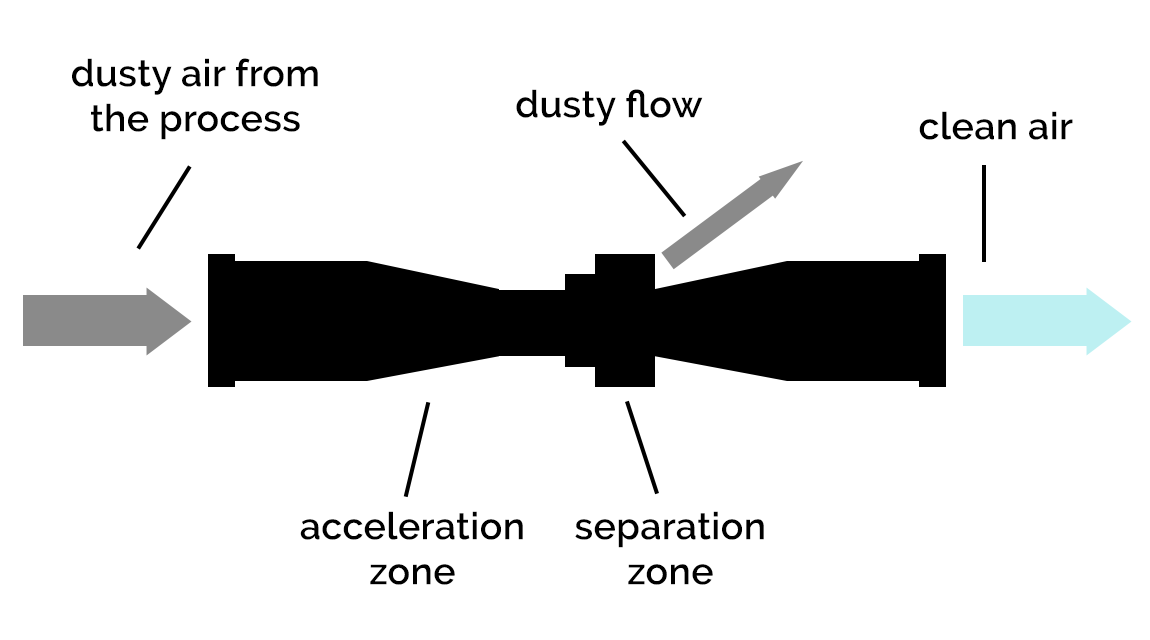

Separation core

In the separation core, gas flow speeds up as it travels through the acceleration zone.

Particles separate by mass and get diverted to a separation chamber, from where the dusty flow continues on to the dusty flow filter.

Meanwhile, clean air flows directly through the center of the cone, on towards the clean air outlet.

Applications

Filtrabit’s dust collectors are suitable for various industries that produce dust.

- Steel manufacturing

- Non-ferrous metals

- Mining and minerals

- Quarrying

- Foundries

A typical application for the system is working concurrently with an existing, centralized dust control system that has been outgrown by increases in the production capacity of the facility.

With smart hooding designs, the high dust density air is prevented from mixing with the ambient air, which minimizes the air volume that needs to be cleaned. This allows for the highest possible dust separation efficiency and reduces the demand on the centralized system.

The units can also be deployed independent from a centralized system. Some use cases allow for the most effective type of application, a closed loop solution, that is essentially free from emissions.

Typical dust to be collected is dry and relatively dense, approximately 1 kg/liter or more. As part of the standard process, Filtrabit performs a test of the client’s dust sample and provides clear indication of the separation performance.

Benefits

- Operating lease model removes the need for large investments.

- Compact and portable modular units can be brought where dust removal is needed.

- Capacity can be scaled according to need.

- Can be used concurrently with existing dust removal systems like bag filters, increasing performance and lowering maintenance costs.

- Excellent efficiency cleaning high dust density gases helps meet environmental regulations.

- Separated material can be easily recovered for further economic and environmental benefits.

- Made from durable steel and able to handle coarse and abrasive particles.