14.02.2025

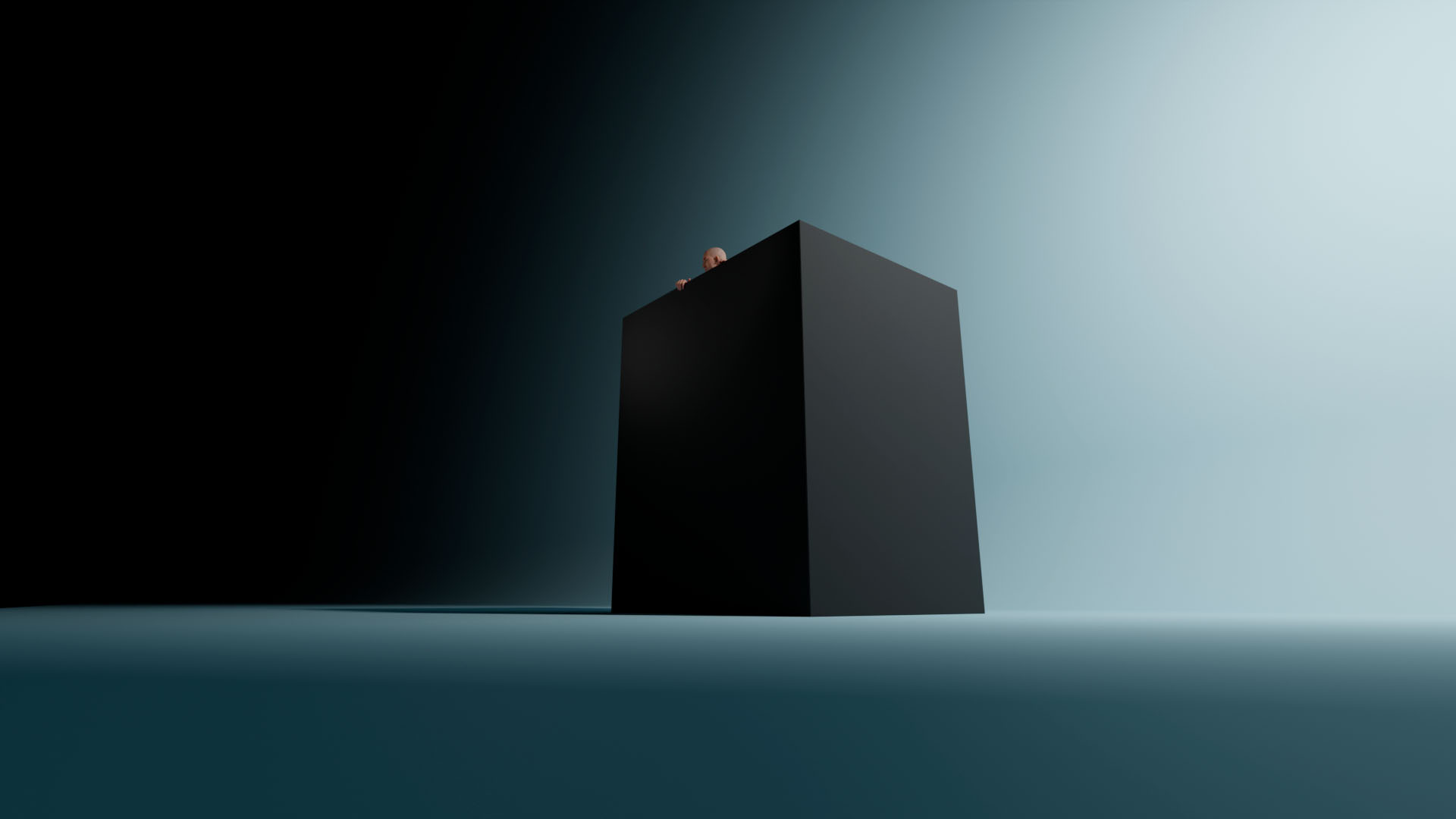

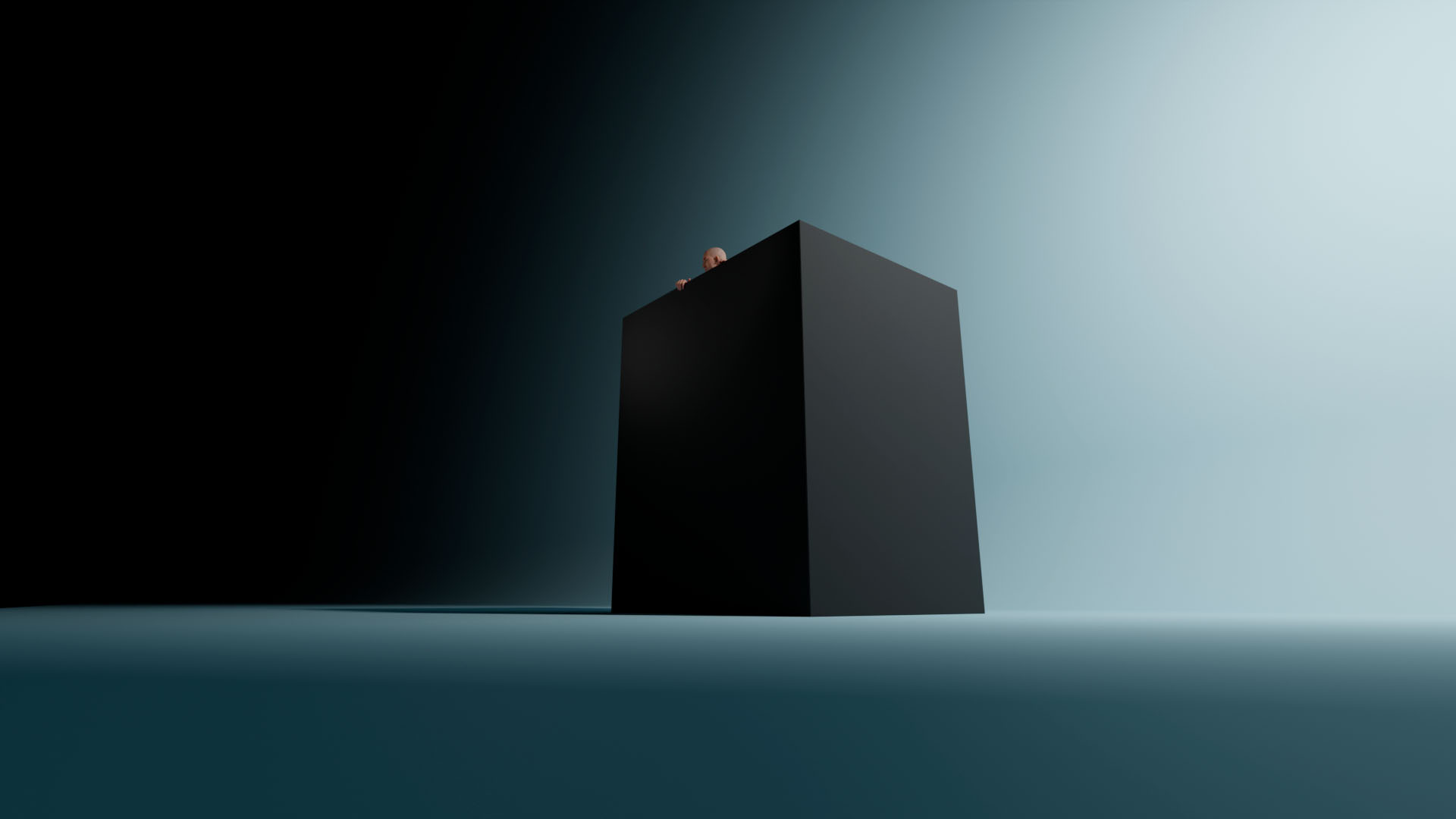

Climb out of the ”black box” – Juha Laukka

Team Filtrabit profile: The justification for climbing out of the ”black box” from R&D Project Manager Juha Laukka, who joined Filtrabit in November of 2024.

14.02.2025

Team Filtrabit profile: The justification for climbing out of the ”black box” from R&D Project Manager Juha Laukka, who joined Filtrabit in November of 2024.

Team Filtrabit profile: The justification for climbing out of the ”black box” from R&D Project Manager Juha Laukka, who joined Filtrabit in November of 2024.

Most technical industries are full of ”black boxes”, big and small. Owners and operators of industrial plants and facilities are required to simply accept equipment and systems whose actual working principles are not revealed. They are forced to make a purchasing decision based on – sometimes inflated – promises of performance and their trust of the general reputation of a supplier. True fit-for-purpose can be lost.

Most ”black box” concept thinking originates from a fear of competition – current or potential. But when you’re working to solve an important problem, such as emissions in heavy industry, and the conventional solutions do not seem to match the challenge, it makes much more sense to climb out of that ”black box”.

Most innovations die away inside the same lab they were born in. Competition does not matter if you never make it to the market. Reaching the commercial stage requires, first and foremost, that you can demonstrate real-world performance with a high level of confidence to outside observers, i.e. your potential customers.

Maturing innovations from a concept idea to a proven product always involves Research & Development. Even at advanced stages of development and with delivered systems already in industrial use, the new applications will require more R&D actions to identify optimal cases and best ways to benefit from novel solutions.

The commercial numbers typically play a major role in the adoption of new technology. Health, safety and air quality – encouraged by regulatory measures – form another major factor that advances adoption. When a novel solution can combine both of these in one, the path to success is much more even. Still, each large industrial facility is somewhat unique and a level of tailoring may be needed to make the most out of the new solution.

The best-case scenario for R&D is working directly with customers for joint development and tailoring the product to their needs. When a system will eventually operate in the same environment where it was developed or fine-tuned in, it can make the best possible match with the customer requests and thereby be justified in terms of economic targets too. The business case is validated immediately. Many of the unknown factors are discovered and dealt with in advance, in co-operation with the customer. This is something which is not possible in a lab environment alone.

The key to engaging a customer into a joint development project is making them understand the technology and the way it functions. Inviting people to be a part of the system tailoring for their own plant is empowering and inclusive. They become convinced more strongly and they naturally evaluate the best ways to apply the new technology into their facility. No-one knows an industrial facility and its real-life challenges better than the people who own and operate it every day.

Getting customers to actively contribute to project specific design and allowing them to be excited about the potential is an efficient way to develop a sales lead into a contract. People get much less involved and excited about ”black boxes” simply because they are not permitted to truly understand and get a feel of the technology.

The concept of a joint development project means that we are in this together. All challenges that arise along the way are also solved together, which really is a big benefit for both. Every challenge that is recognized and overcome during the development stage means that there are less things to worry about in the final setup.

What you’re sacrificing with openness is the ability to obfuscate, which is unnecessary in the first place, when the technology provides truly meaningful value. Of course, opening up your innovation to the world increases the chance of copycats, but that is the price of doing business. The early mover advantage and unique know-how of the original innovator help to maintain an edge.

On a practical level, many problems can be avoided by sharing information. People want to help by nature, and they are able to contribute much more effectively when they understand how their own area of expertise relates to the bigger picture. Relying on people to always know when and how to ask, if unclear, is a recipe for disaster.

For Filtrabit in general, the more we include the customer in the early stage of the sales process, the better for both. This includes e.g. collaboration on validating the value proposition for a specific customer project and doing particle capture tests with samples from the customer’s process and sharing the results.

Avoiding the ”black box” principle can even be practiced on a personal level. The more open and explicit you are about your assumptions and reasoning, the more convincing you are when correct, and more quickly corrected when wrong.

Who: Juha Laukka, R&D Project Manager at Filtrabit.

Education: M.Sc. in energy technology, majored in applied thermodynamics, minors included environmental technology and power plant technology. Helsinki University of Technology (Aalto University).

Experience: 25 years in sustainable energy solutions, industrial pollution control and decarbonization. Held various product management and R&D positions in companies including Fortum, Kvaerner, Metso Power, Valmet Technologies and Rotoboost. Additional consultancy and advisory experience for wide-ranging international clients.