23.10.2024

Materia: “Filtrabit brings new alternatives to industrial dust extraction”

The Finnish mining and metallurgical publication Materia has published an article on the innovation and future prospects of Filtrabit.

23.10.2024

The Finnish mining and metallurgical publication Materia has published an article on the innovation and future prospects of Filtrabit.

The Finnish mining and metallurgical publication Materia has published an article on the innovation and future prospects of Filtrabit.

The original, Finnish language article can be read here on pages 86 and 87.

Below is the English translation of the article.

Filtrabit is a spin-off from SSAB Corporation’s research unit. It has a unique, patented dust removal solution for heavy industry: the flow separator. It was developed in a joint project with the University of Oulu and the EU. The technology helps to solve the global problem of fine particulate emissions in heavy industry and is vital for reducing CO2 emissions.

Industrial emissions of fine particles face stricter regulations and permits. Industry needs to be able to filter fine particles in order to continue operating. Despite this, there have been no major advances in industrial dust collection in decades. Existing solutions are typically very large systems, the size of a small apartment building. They require 1-3 years of construction, which is both slow and expensive.

In addition to the investment phase, they entail significant costs due to the high level of disruption to production.

Energy efficiency is also a challenge for existing systems. Warm air often escapes as such into the atmosphere. Alternatively, it is captured with low efficiency. This causes fine particulate emissions, high energy costs, and CO2 emissions. In addition, these solutions are often poor in practice. For example, the filters of large bag filter systems can easily clog or crack under high dust loads. In this case, their filtration efficiency is much lower. So, dust control often fails in practice and often raises particulate-levels near the plant. This harms workers’ health and incurs costs for companies.

Filtrabit set out to develop a new dust removal method for SSAB, and the research unit at SSAB initially conceived the innovation. The founders established the company in 2011. In addition to Veikko Valli, the father of the SSAB-based innovation, Professor Pekka Mäntylä from the University of Oulu joined the company. A project funded by the EU Horizon programme (with highest score in the program history) tested and piloted several generations of products. Filtrabit has developed a unique flow separator. It removes fine particulate emissions from industrial processes by using the laws of flow dynamics.

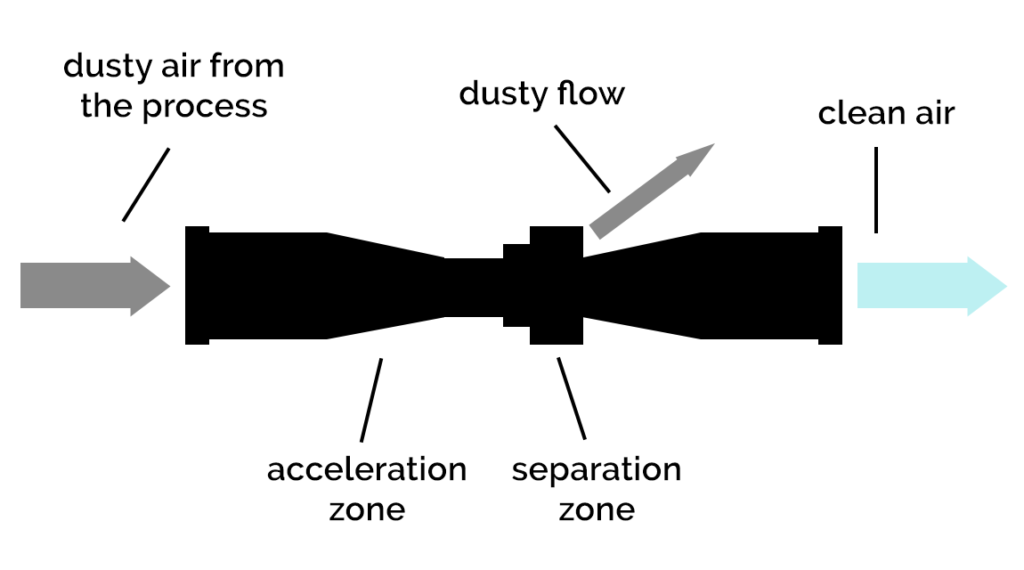

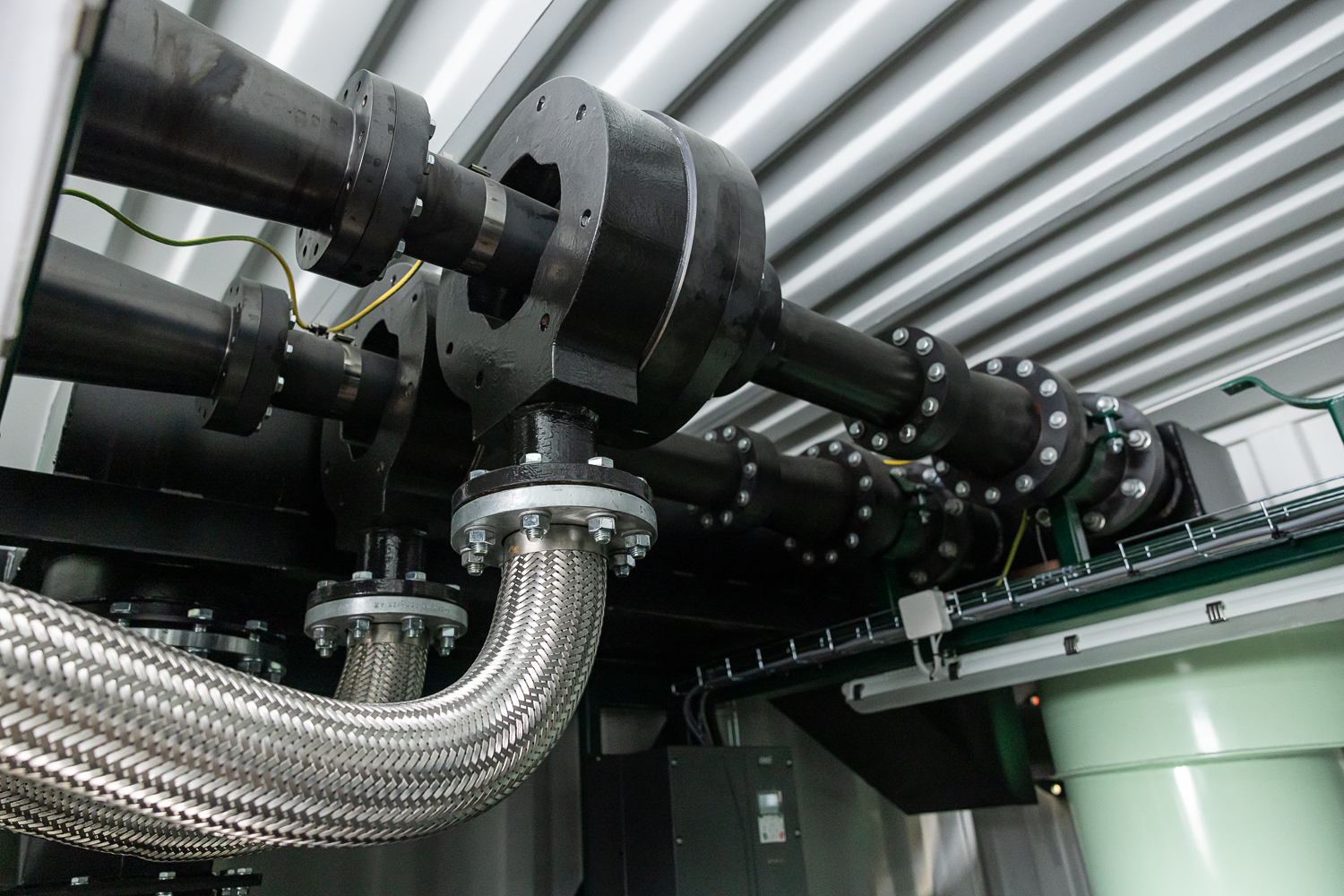

The flow separator has fixed flow passages and a conical structure. It lets the dusty gas stream do the most possible work for separating solids from the gas. The flow separator consists of an acceleration zone, a settling zone and a separation zone. First, the dusty gas is accelerated and flow is guided to achieve optimal shape. Then, the flow separator separates the solids-laden stream from the clean gas. The clean gas goes through the flow separator. The dust stream is diverted to a separate side stream.

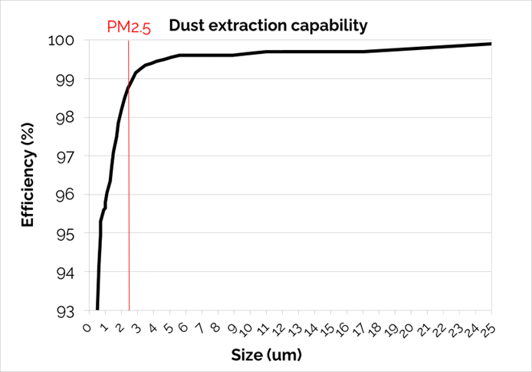

The company holds an international method patent and all product rights to the solution. The device has achieved a very high separation efficiency of fine particles in practice. Its performance remains high and unchanged from month to month and year to year.

Filtrabit has developed a dust removal system based on a flow separator. It has been tested in heavy industry. It allows industrial dust management solutions to be upgraded for the modern age.

Many heavy industry production processes have changed over the years from the original. Production capacity may have multiplied over the years. In such a situation, the original dust extraction system may be either out of date or otherwise out of capacity. Remedying the situation might normally require a major overhaul of the whole system. Many industrial plants are now surrounded by private homes in domestic areas and there is no more room for larger, centralized dust collection systems.

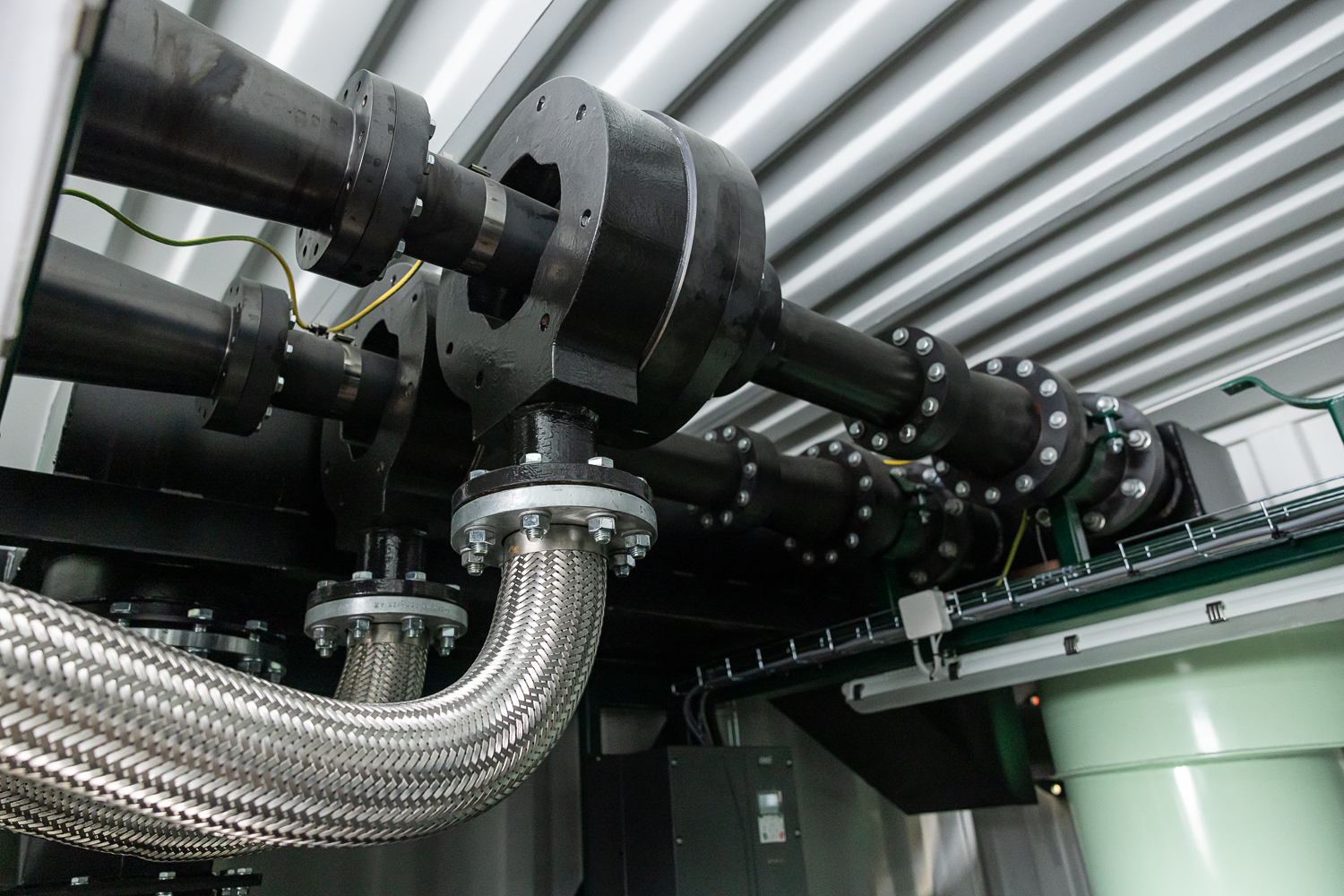

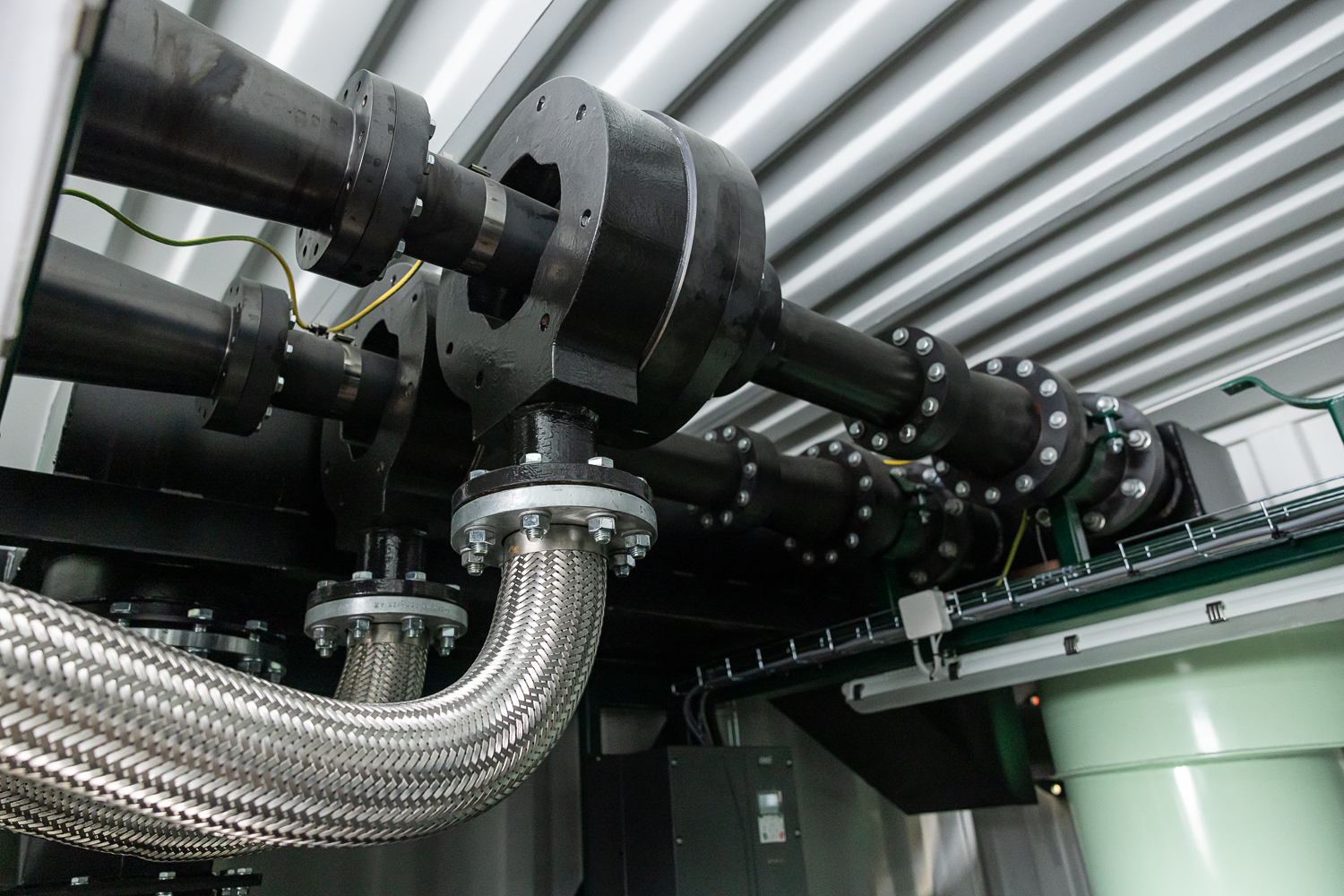

Filtrabit’s modular, shipping-container integrated system offers a solution that brings an efficient local dust removal system to the problem areas of dusty processes. This system not only eliminates the local dust problem, but also improves the performance of the existing dust removal infrastructure. Filtrabit’s leasing-based dust collection systems provide a cost-effective way to manage industrial dust problems and may even eliminate the need for investment in a complete system upgrade.

The first integrated solution has been in production at SSAB’s Raahe unit for several years. It has collected hundreds of tonnes of coke dust that would otherwise have ended up on the plant floors and in the environment to be cleaned up. In addition, an efficient local dust removal unit added at the right point in the process has reduced the load on the original dust removal system. This has enabled it to perform significantly better and reduce maintenance costs. As the dust collected is recovered in a clean state, it can be reused in downstream processes. In many cases, the collected dust is a valuable process material, which not only eliminates the dust problem, but can also provide significant economic benefits. In June 2024, the delivery of the new first generation modular unit to the Raahe plant was announced.

In addition, two new modular units are already in the delivery phase for industrial production for new customers in the Finnish market. In June 2024, the first contracts for the Indian market were also announced.

India’s economy is growing rapidly. Local industries seek solutions to their dust problems. Besides India, Filtrabit is testing and discussing contracts in Europe with customers in the steel, iron, foundry, non-ferrous metal, and mining industries. The market potential for industrial dust extraction is very large worldwide and the aim is to create a new major green technology growth company in Finland.

Materia issue 4/2024. Published on October 17, 2024.

Photograph by Petteri Löppönen.