New industry standard

Flow-dynamic dust separation has arrived. Extensive research together with universities and partner clients has resulted in an innovation that brings industrial dust control to the 21st century and the time of the 4th industrial revolution.

To meet the new standard for regulations in air pollution and CO2 emissions, industry needs to adopt new technology. The necessary scientific breakthroughs have already been made thanks to advanced computer simulations like Computational Fluid Dynamics (CFD). Now it’s time to put them into action.

Company Technology

Company

Filtrabit is a flow-how company in the greentech sector. Our focus is on solving particulate pollution of heavy industry, improving air quality inside and outside industrial plants.

Read more

Technology

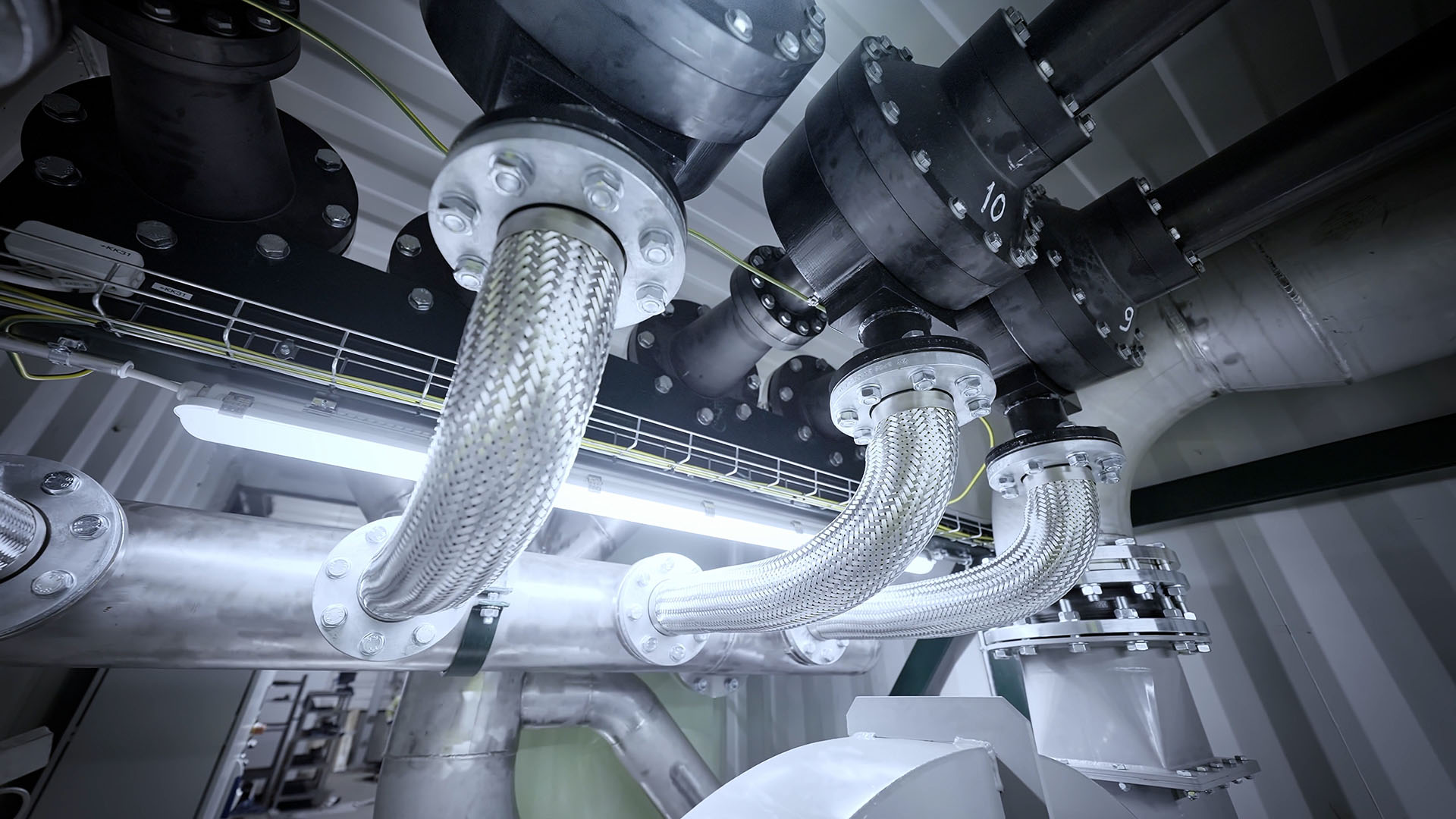

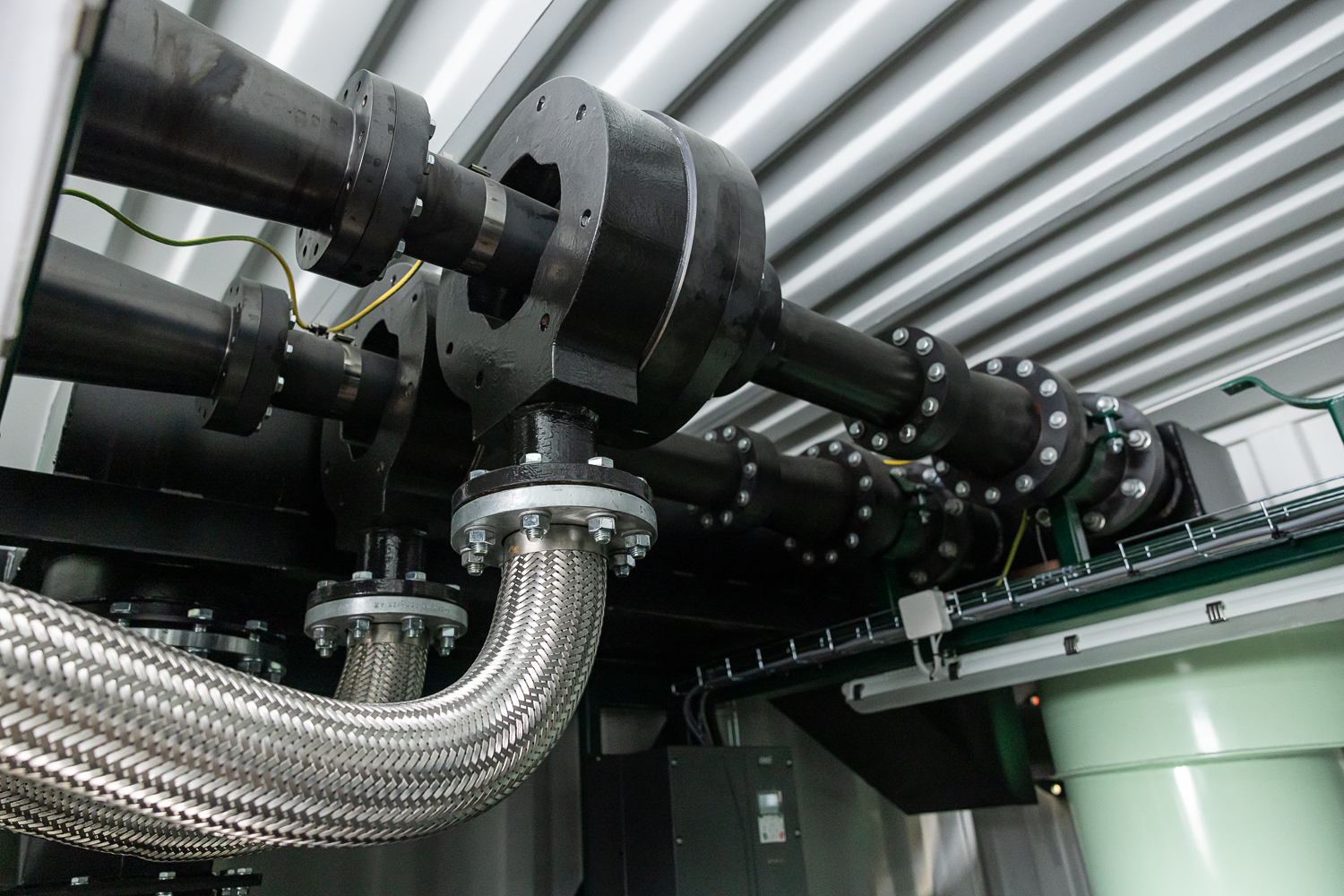

Filtrabit’s solution is based on flow dynamics. The separation core at the heart of the innovation effectively separates the dust from the air and allows for the dust extraction equipment to fit into a modular unit.

The intake air is directed and accelerated in a way that causes the dust particles to separate into a highly condensed side stream, where they can be captured without the large surface area of filter material required by traditional systems.

The system operates at a steady performance level and the captured dust is continuously discharged into a container, ready for immediate reuse as valuable raw material, as opposed to mixing with other types of dust in a centralized system.

Read more

Products

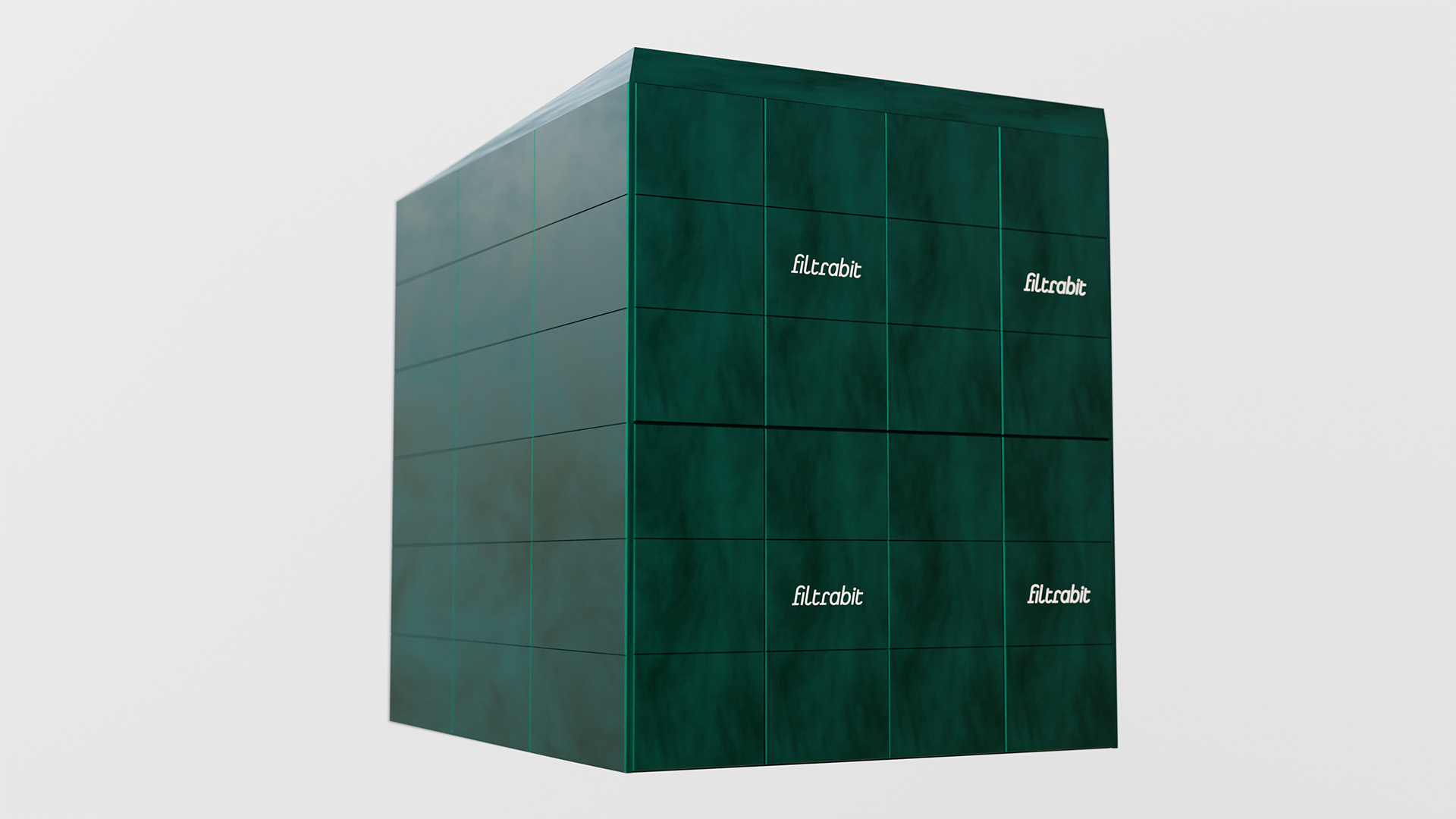

Filtrabit’s flow-dynamic dust separator is available as a dual-core DC201 model and a quad-core DC401 model. These portable units are available on an operating lease model.

Read the full brochure from the link below.

Brochure

Value proposition

Our flow-dynamic dust separator makes removing industrial dust and microparticle emissions more effective, economical and easy.

It means better employee and community health as well as lower CO2 emissions through the reduced need for virgin resources.

Meeting environmental regulations, fewer production breaks due to maintenance and more flexible placement and financing.

Capital efficient solution

Filtrabit offers dust separation units on an operating lease model and together with partners, helps clients design the necessary hooding and ducting.

Contact us

News

Industries

Flow-dynamic dust separation is the new standard for industries that generate heavy, dry and fine dust. Operations that include crushing, sieving and transporting such materials on conveyor belts are particularly great beneficiaries of the technology.

Examples of customers include steel mills, foundries, quarries, mining and ore processing operations.

Steel production

Steel plants include numerous sources of dust, such as furnace dust and storage yard dust from handling raw materials and slag. Coking, sintering and pelletizing plants are prime examples of dust generating sites where flow-dynamic dust separation can provide order-of-magnitude level improvements.

Foundries

Sand handling, mold crushing and surface treatment of the molded components are common problem areas for dust control in foundries. Flow-dynamic dust separation can make a substantial difference in the working conditions and environmental impact of these facilities.

Mining and ore processing

Production of non-ferrous metals like copper and zinc also includes many operations that generate heavy dust. Handling of the ore and other raw materials requires crushing, sieving and conveying at various points.

Quarrying

Crushing and sieving are common operations and culprits for fugitive dust in quarries. Vulnerable conveyor transfer points are also ubiquitous.